The Resource and Service Centre (RSC) provides participants from science and industry with recognized methods for resource and energy efficiency as well as sustainable production. Here is a small selection of the method portfolio:

Material Flow Analysis (MFA)

To improve a process, it needs to be presented accurately. For this, the path that the materials travel (material flow) will be reconstructed and displayed, e.g. through Sankey diagrams. They summarize work steps and document the input and output. The amount of material is reported in the associated unit (e.g. kilograms).

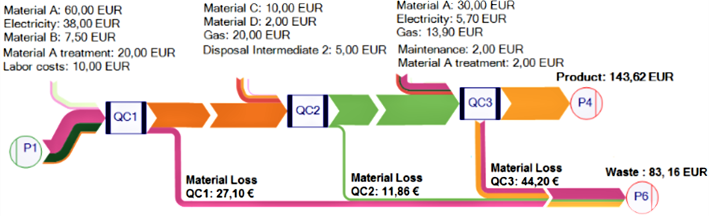

Material Flow Cost Accounting (MFCA)

MFCA is now building on the knowledge of the MFA by listing the materials in a monetary unit. MFCA is an ISO-standardized and increasingly established method for valuing the efficiency of production processes in terms of material losses. Any output that does not end up in the desired product is considered loss. In each production step, the expenses (energy, raw materials, consumables and supplies) are allocated to the wanted and unwanted products in accordance with the costs. This allows the determination of the true value of the waste. By combining the monetary valuation with the climate assessment of the material losses, valuable information will be provided to the companies for decision support.

Life Cycle Analysis (LCA)

Life Cycle Analysis (or Life Cycle Assessment) is a systematic analysis and assessment of the environmental impact of products throughout their lifecycle (‘cradle-to-grave’). In the process, described in DIN EN ISO 14040/14044, not only manufactured products but also services can be analysed.

The holistic analysis of the entire product`s life cycle ensures that negative environmental impacts are not shifted unnoticed into another lifecycle phase of the product. All relevant environmental withdrawals and emissions to the environment are considered.